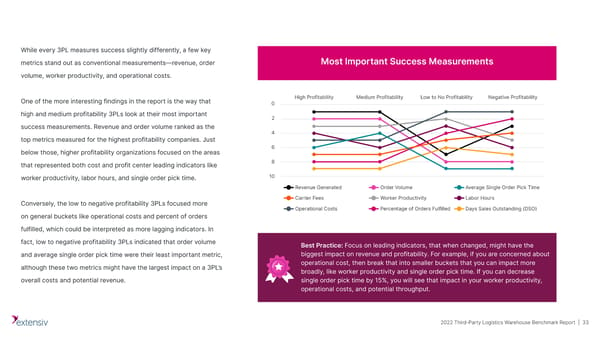

While every 3PL measures success slightly differently, a few key metrics stand out as conventional measurements—revenue, order volume, worker productivity, and operational costs. One of the more interesting findings in the report is the way that high and medium profitability 3PLs look at their most important success measurements. Revenue and order volume ranked as the top metrics measured for the highest profitability companies. Just below those, higher profitability organizations focused on the areas that represented both cost and profit center leading indicators like worker productivity, labor hours, and single order pick time. Conversely, the low to negative profitability 3PLs focused more on general buckets like operational costs and percent of orders fulfilled, which could be interpreted as more lagging indicators. In fact, low to negative profitability 3PLs indicated that order volume Best Practice: Focus on leading indicators, that when changed, might have the and average single order pick time were their least important metric, biggest impact on revenue and profitability. For example, if you are concerned about although these two metrics might have the largest impact on a 3PL’s operational cost, then break that into smaller buckets that you can impact more broadly, like worker productivity and single order pick time. If you can decrease overall costs and potential revenue. single order pick time by 15%, you will see that impact in your worker productivity, operational costs, and potential throughput. 2022 Third-Party Logistics Warehouse Benchmark Report | 33

Third-Party Logistics | Upload & Go Page 32 Page 34

Third-Party Logistics | Upload & Go Page 32 Page 34